PSR Feeder

Expendables

50 years of consistency and reliability.

50 years of consistency and reliability.

‘Feeder Expendables’ is the name given to refractory parts used in the gob forming process. They are ‘expendable’ because they are changed frequently during the life of the furnace depending upon the requirements of the forming operation.

As the final link between the glass conditioning and forming processes, feeder expendables have immense influence on the success or failure of the entire forming operation. They must be able to resist the corrosion from molten glass at the same time as being able to withstand the thermal shock of immersion in molten glass.

Our refractory compositions are slip cast not chemically bonded or pressed, ensuring a homogeneous ceramic body with a densely packed surface texture. Slip cast into plaster moulds, dried in humidity controlled drying chambers and sintered at high temperatures, PSR feeder expendable refractories are renowned for their consistency, reliability and longevity.

PSR-930 – 24.9% ZrO2

This is the latest new development to come out of PSR’s R&D department. It has a higher zircon content, but of equal importance is the particle packing density that we achieved through detailed analysis of the refractory microstructure. With a porosity as low as 13% and a density as high as 3200 kg/m3, compared to typical values of 18-20% and 2900-3000 kg/m3 respectively for competitive high zircon containing refractories, we were able to achieve excellent glass corrosion resistance whilst maintaining the thermal shock resistance inherent in our traditional refractory compositions.

Our full range of feeder expendable refractories are available in PSR-930 and results to date have shown an increase in the life of feeder expendable parts of 30-50% over our standard compositions in most standard soda lime container glass operations.

PSR-925 – 24.1% ZrO2, 74% Al2O3

PSR-925 was initially developed as a spout insert material as an alternative to other options such as fused cast AZS inserts or Chrome-Oxide inserts. Using Zirconia, a highly refractory material, as the base for the material, as opposed to the usual ingredient Zircon (Zirconium-Silicate) and adding only alumina grains and powders, we achieved exceptionally high corrosion resistance.

By manufacturing the material ourselves, using our slip-casting method, we are able to cast PSR-925 as a single piece ‘uninserted’ spout. This eliminates the joint. otherwise present between the spout insert and the spout body, and ensures the entire spout bowl is highly resistant to glass corrosion.

PSR-925 and spout inserts have proven to operate as a spout or spout-insert for in excess of 3 or 4 years, matching or even surpassing the life expectancy of a chrome-oxide inserted spout.

PSR are also able to offer Chrome-Oxide inserts, inserted in a PSR-315 spout bowl. However Chrome-Oxide material comes with its own drawbacks – being expensive to produce, the environmental considerations inherent with some chrome containing refractories, and potential to discolour some glasses. PSR-925 has none of these considerations, can be offered at a fraction of the price of a Chrome-Oxide inserted spout and represents the optimum solution for a spout bowl.

PSR-333 – 11.25% ZrO2

PSR-333 is the international standard for feeder expendable refractory material. A direct bonded zircon-mullite composition, the constituent oxides react at high temperature to form a strong ceramic bond, combining excellent resistance to alkali corrosion with resistance to thermal shock.

PSR-315 – 18% ZrO2

PSR-315 combines higher zirconia content with higher firing temperatures to achieve enhanced corrosion resistance without compromising thermal shock properties. PSR-315 can be specified for most feeder expendable parts but is particularly beneficial for spouts, tubes and high tonnage applications.

PSR-333 FG

PSR-333 FG is a derivative of PSR-333 with similar characteristics to PSR-333 but is reformulated for the casting of small complex shapes such as orifice rings.

PSR-311 91% Al2O3

PSR-311 is a high alumina refractory that is used mainly in tableware production where the presence of zirconia causes excessive seeding after refractory replacement.

PSR-993 99.7% Al2O3

PSR-993 is the bonded alternative to fused-cast α-β alumina. Developed for use as the glass contact material for distributors and forehearths PSR-993 exhibits equivalent corrosion resistance to fused-cast alpha-beta alumina and is commonly used for long life spout bowl applications. Its lower thermal shock resistance make it generally unsuitable for other feeder expendable applications.

PSR-SM62 62% Al2O3

PSR-SM62 is an andalusite based composition sintered at high temperature to facilitate the development of mullite and was specially developed for forehearth superstructure applications. In the feeder its excellent thermal shock properties also make it the ideal refractory material for spout cover blocks and spout burner blocks.

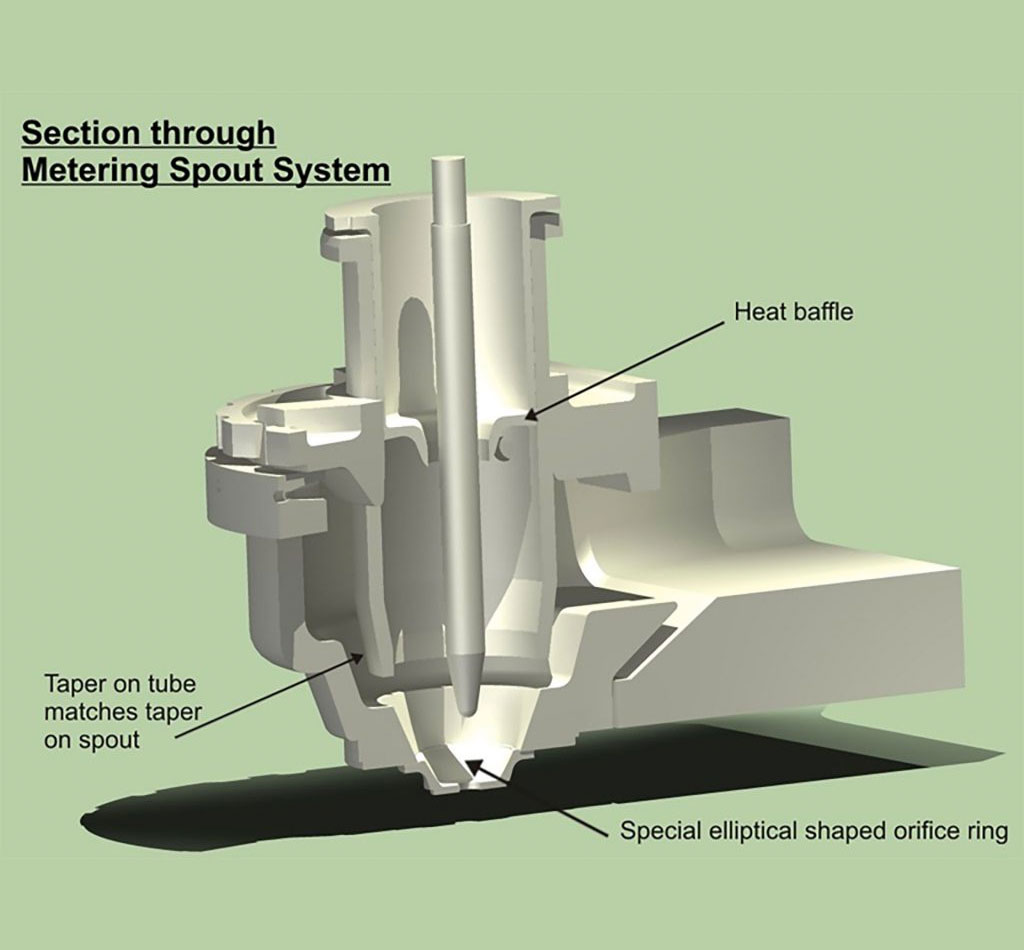

At the forefront of modern gob feeder technology is the Metering Spout System; a special design of feeder expendable refractory parts bringing new levels of sophistication to the gob forming operation. The metering spout system has the following unique features:

PSR Preforms are pressed ceramic fibre shapes moulded to fit the exterior contours of the orifice ring and the interior contours of the orifice ring holder. Made from bio-soluble grade fibres they provide a clean and highly efficient form of orifice ring insulation, reducing heat losses from the holder and improving the thermal homogeneity of the gob forming operation. Formed to fit the precise shape of the orifice ring they also provide support over its entire exterior surface, reducing the risk of orifice ring cracking through mechanical failure.

Gaskets are also available as a sealing ring between the orifice ring and the spout. Manufactured from bio-soluble grade fibres PSR gaskets are available in a range of diameters and thicknesses and are a clean, efficient alternative to the use of the traditional orifice luting cement.